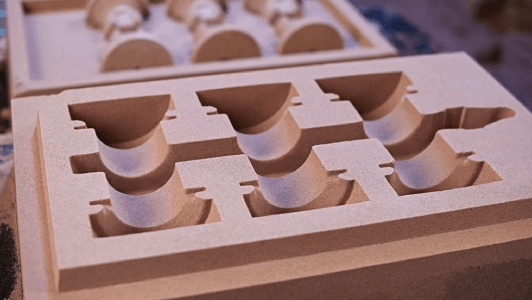

Investment casting is mostly connected with making diverse metal things with complex calculations in the metal projecting field. Different elements influence yield rate and cast quality, including the plan of the gating System in the projecting cycle.

Great quality can diminish projecting imperfections and increment yield rate. Because of different advantages over the assembling technique, the Investment casting interaction rapidly creates numerous mind boggling parts.

Sorts of gating System in projecting interaction

There are two distinct sorts of gating systems in the projecting cycle: compressed and unpressurized gating systems.

1) Pressurized gating system

Here the total cross-sectional region decreases towards the shape depression. The limitations in the metal stream will keep up with the backpressure. It’s like the progression of fluid (volume) from all doors. Particularly the backpressure is crucial for decline the desire. The explanation is when sprue each time runs totally.

Because of the limitations, the metal streams at expanded speed cause a ton of choppiness and odds of form disintegration. Normally, projecting yield is given since the volume of metal spent in the sprinters and doors is decreased.

Because of the choppiness, this sort of gating System in foundry isn’t for the most part utilized for light composites yet might be as often as possible used for ferrous castings.

2) Unpressurized Gating System

Here, a total cross-sectional region creates the shape depression. There is a limitation just at the lower end of spring. Fluid volume stream is alterable from one entryway to another. Desire in the gating System as the framework never runs altogether. Similarly, there is low choppiness. Because of the choppiness event, this sort of gating System in the foundry is utilized for light compounds.

Investment casting is a habitually utilized interaction to make various sorts of metal plans. Gating in the projecting system is a sort of intricate technique to comprehend. In the gating System, sprinters and risers are fundamental when making diverse top notch plans.

The above makes reference to two distinct sorts of gating systems in the projecting cycle which are also used by making lead casting companies like dawangcasting.com. So what are the parts of the gating System? For the most part, the parts of the gating System have eight huge components.

Principle components of gating System

There are two critical stages in giving a role as filling process and the hardening strategy. In the filling system, the components of the gating System incorporate a pouring cup, spare base, sprinter, sprue, door, and riser.

Pouring cup

In shape, it is rectangular or round. It adds the liquid metal, which is poured, from the scoop. The mostly pouring cup is utilized for diminishing the energy of the fluid streaming into the shape by settling first into it.

Sprue

The pouring bowl should be profound just as the entry into the sprue is a smooth range of at minimum 25mm. As per the proposals, the pouring cup profundity ought to be 2.5 occasions the sprue entrance measurement. For the most part it is helpful for smoothing metal streams and shielding from vortex arrangement.

Gating System

In the cross-area, it is round. It makes the liquid metal tumble from the pouring cup to the sprue appropriately. The sprue ought to be an upward shape section through the adapter to build the speed of the metal. The explanation is it streams down, diminishing the air goal. It associates the pouring bowl to the sprinter moreover. The shape can be acquired by the progression condition.

Sprue Well

It alters the course of the liquid metal stream to the opposite point and passes it to the sprinter. At the lower part of a spruce well is vital for decline the speed of the entered metals and the form of disintegration.

The standard rule for the sprue well is multiple times that of the sprue stifle region. As per the proposals of Investment casting gating System plan, the fantastic profundity ought to be exactly like that of the sprinter.

Sprinter

This part is valuable to take the liquid metal from the sprue to the projecting. We can consider the last advance where the liquid metal goes from the sprinter to the form hole.

Door

Doors are the liquid metal openings into the form cavity. The main thing is it may very well be effectively severed subsequent to projecting cementing.

Various sorts of doors are utilized in the projecting system, contingent upon the utilization.

Riser

This is the wellspring of additional metal. It streams from the riser to the form pit to make up for shrinkage. This strategy happens in the projecting when it starts hardening. Assuming that the gating System does not have a riser, Some weighty pieces will get shrinkage anomalies. That can be on a superficial level just as inside.

Read more, The riser ought to be made to freeze in the wake of completing the focal projecting to fulfill its capacity. The riser ought to stay liquid until later the projecting hardens.

There are two principle elements of the riser. It makes up for cementing shrinkage, and the subsequent one is the hotness source.